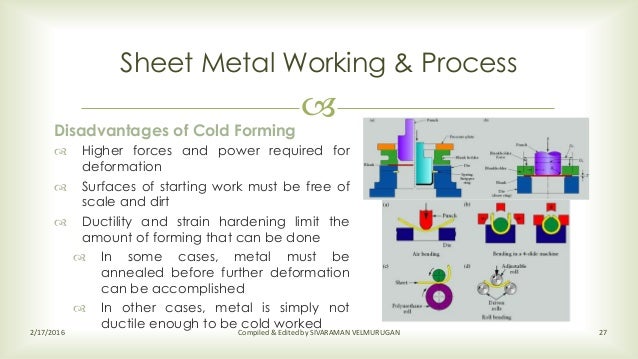

Sheet metal forming process advantages and disadvantages august 31 2020 2 comments in guest authors by ricardo barbosa sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

Advantages and disadvantages of sheet metal.

To deformed the raw material.

Advantages of metal shearing process shearing performs straight line cuts without forming chips or burning or melting the material.

Magnetic can be con 7.

While they are not nearly as costly as wood shakes high end tile or slate metal roofs do have a higher up front cost compared to most asphalt shingles.

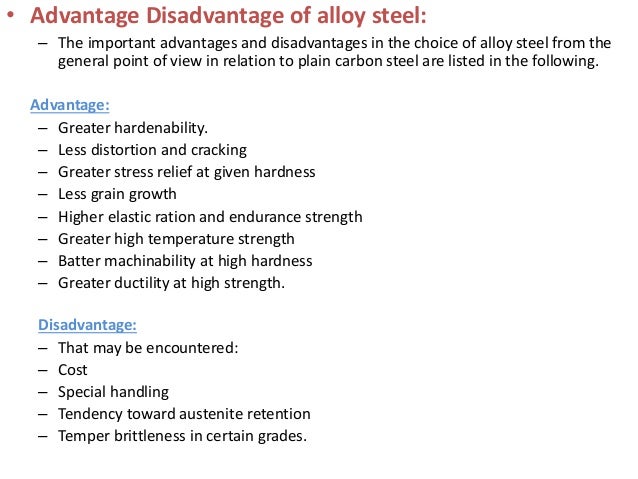

This depends highly on application and which alloy you mean but i ll answer generally.

Strong per mass 3.

This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.

One of the major points of consideration in choosing a metal roof for your house is the kind of metal sheet you are buying.

That s one of several reasons it s been a trusted form of metalwork for hundreds of years.

In general the deep drawing method is highly valuable for large quantity or long run production orders for multiple reasons.

In this process we apply stresses like tension compression shear etc.

Metal forming using deep drawing has its advantages and disadvantages.

Read on to find the pros and cons of sheet metal roofing.

This article gives you the benefits and drawbacks of using a metal roofing system.

We are here to break down the advantages and disadvantages of sheet metal roofing from characteristics to the installation process as well as maintenance tips.

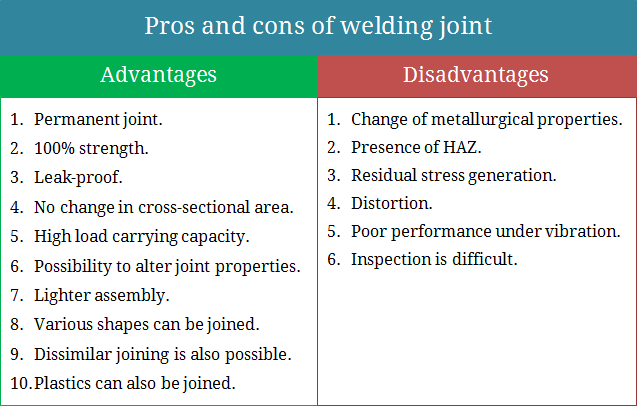

Metal can go through a wider range of processes including chipping deep drawing casting forging welding and soldering.

But what are the advantages and disadvantages of metal and such other steel roofing materials.

However a metal roof does offer a longer lifespan.

Amazingly tunable heat treat alloy cold.

Cheap for a metal 4.

Pros of sheet metal roofing versatility.

Types of metal roofing components.

Forming process also known as metal forming is a large set of the manufacturing process by which a raw material converted into a product.

Stiff per mass 2.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

This allows the process to work well with most softer metals such as aluminum brass bronze and mild low carbon steel.