Afa boasts superb properties maintaining excellent clarity with minimal colour temperature shift after prolonged uv exposure making it a superb choice for an led coating application.

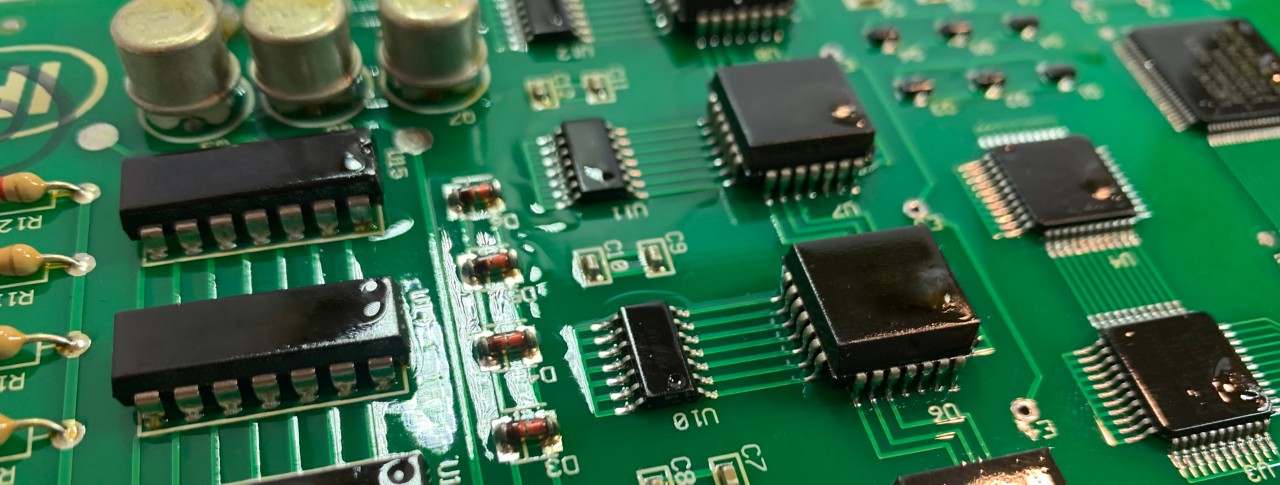

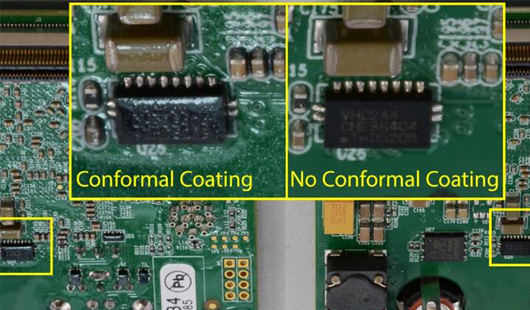

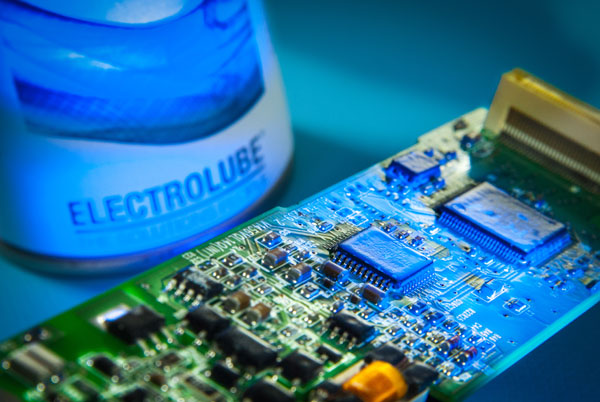

Acrylic conformal coating pcb.

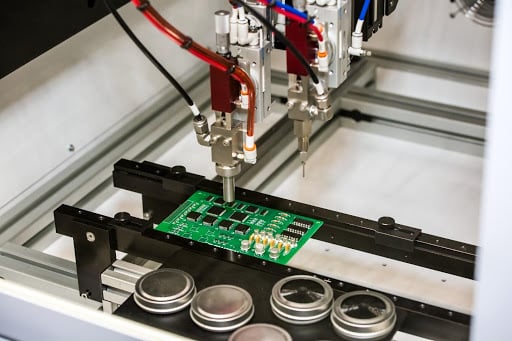

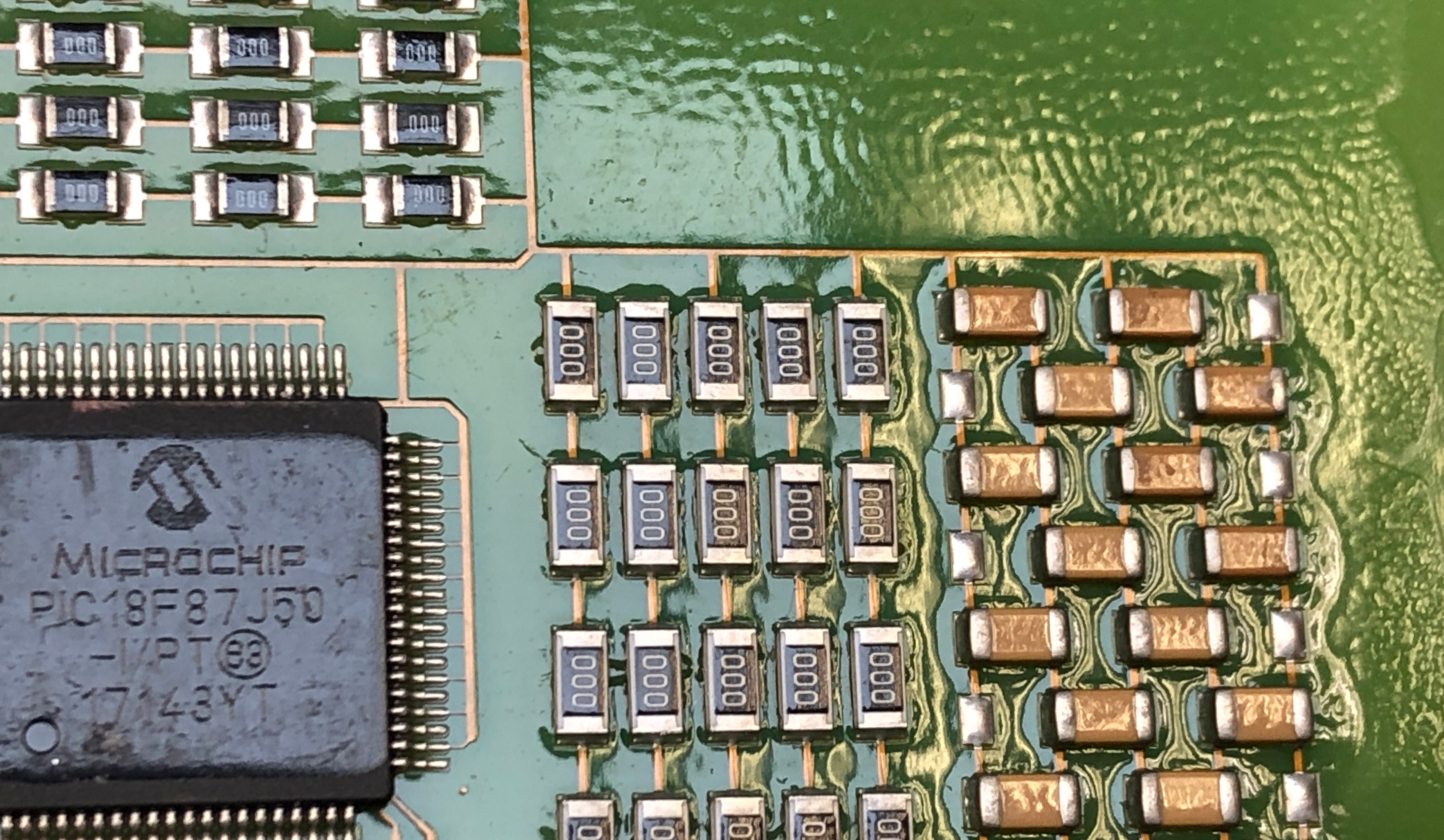

Different conformal coating types such as acrylic conformal coating urethane conformal coating and silicone conformal coatings are frequently used in conjunction with different conformal coating systems to apply the coatings in a quick easy manner for larger scale production.

Benefits of conformal coating.

Acrylic coatings are easily and quickly removed by a variety of solvents often without the need of agitation.

Acrylic and urethane conformal coating are widely used conformal coatings.

There are five types conformal coating.

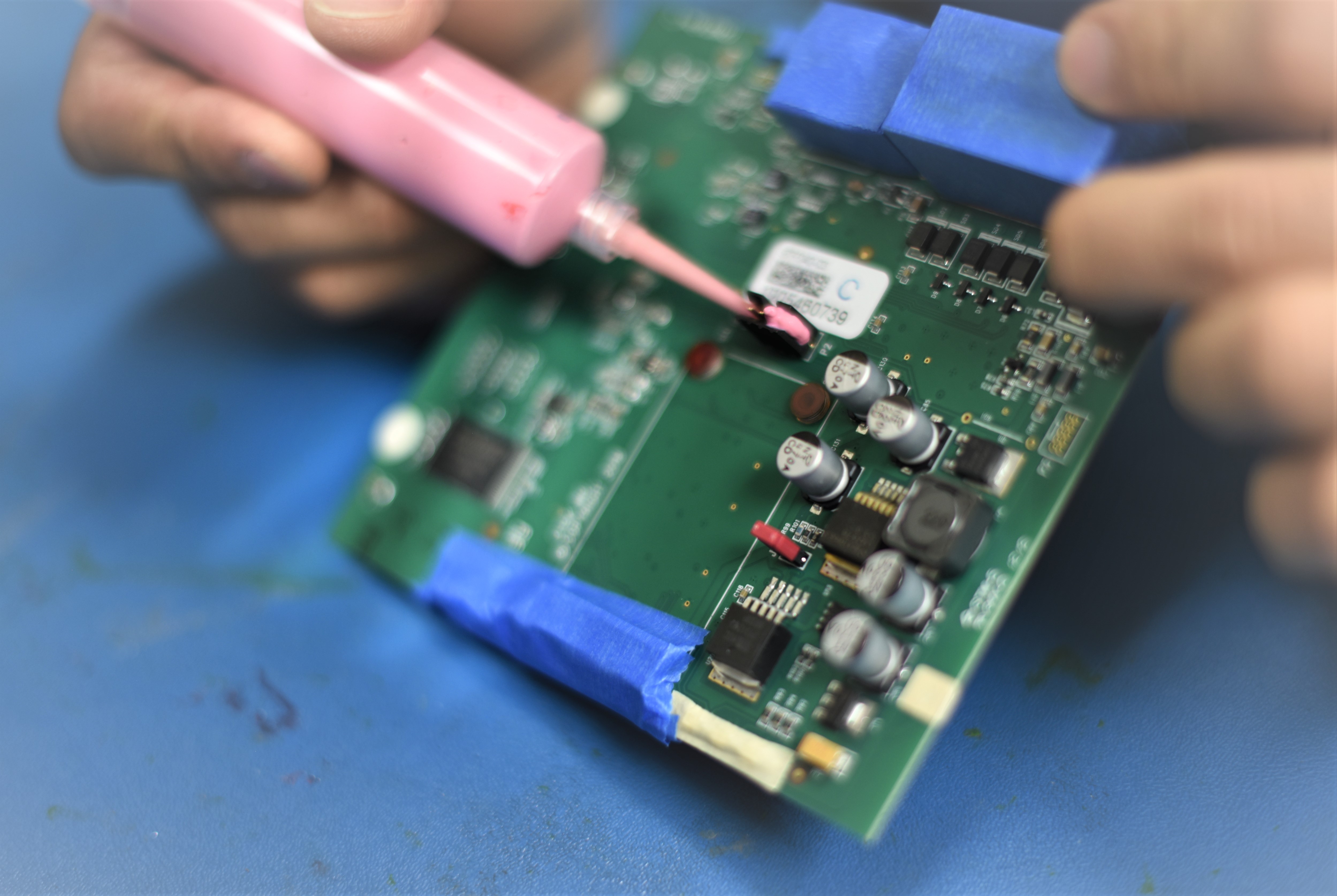

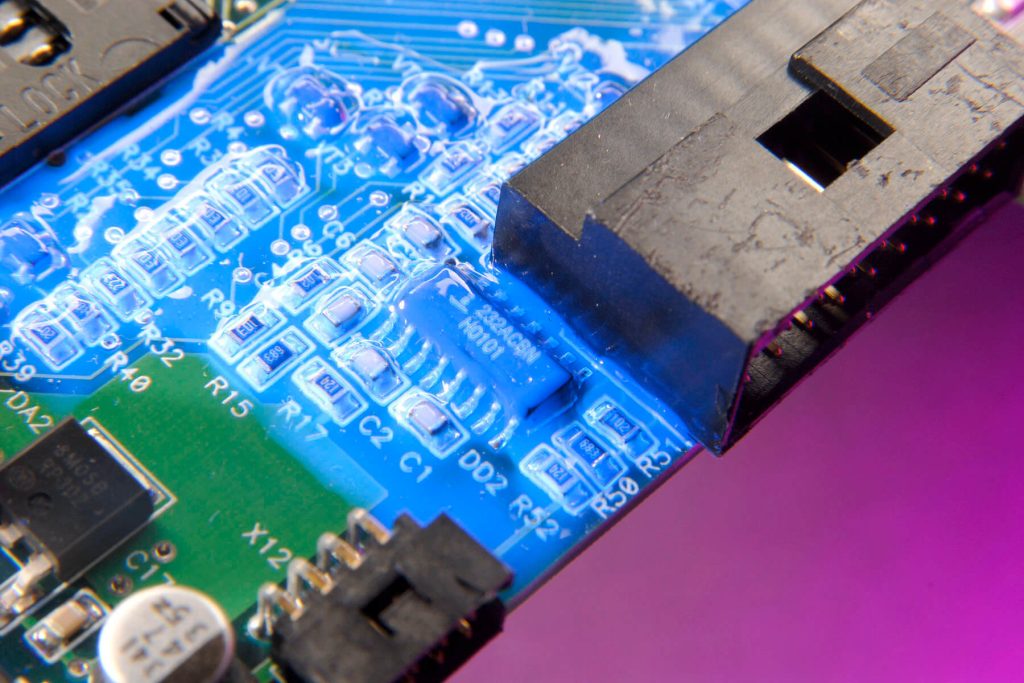

These coatings can be brushed on sprayed on or the circuit boards can be dipped in the coating.

Coatings can be applied in a number of ways including brushing spraying.

The acrylic conformal coating is applied by using a hand brush sprayed or dipping the board in an acrylic resin coating.

This is the most used conformal coating for pcbs.

To secure a conformal coating pcb or printed circuit board pcb from the components including dampness residue and extraordinary temperatures the conformal coating needs to apply regularly.

Conformal coatings can be made from acrylic silicone or urethane resins as well as other more application specific compounds such as epoxy depending on the needs of the circuit board.

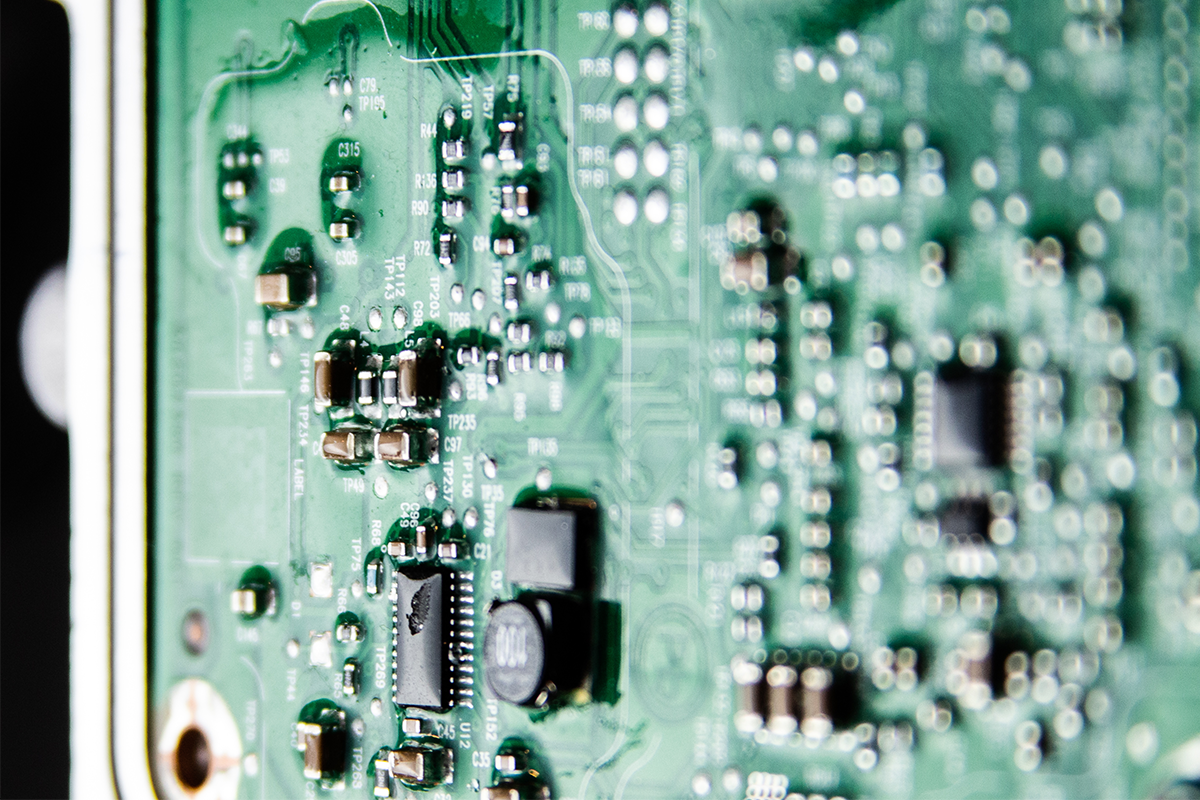

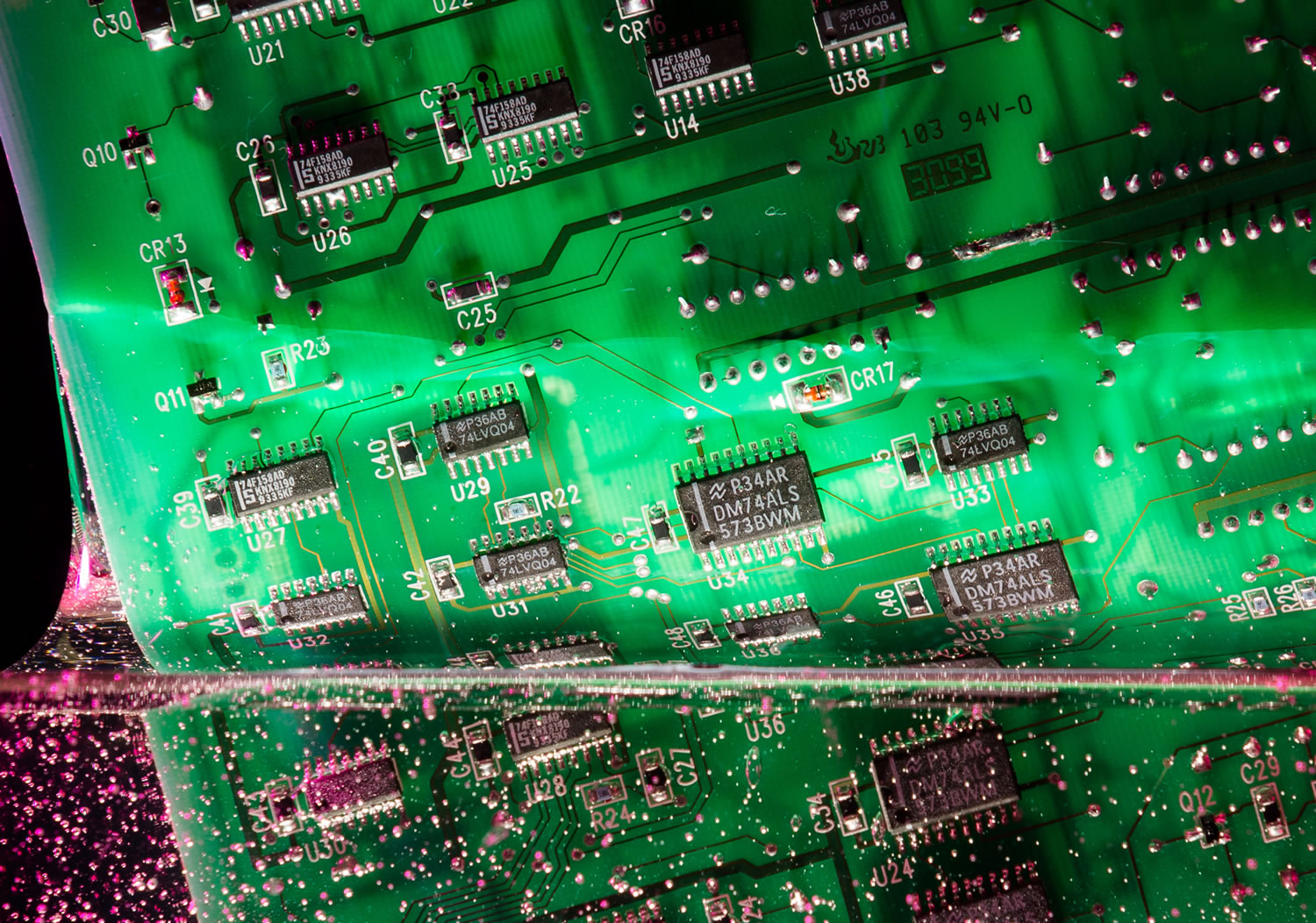

Typically applied at 25 250 μm micrometers thickness it is applied to electronic circuitry to protect against moisture dust chemicals and temperature extremes.

Four of the five acrylic epoxy polyurethane and silicone are applied by either brushing spraying or dipping the coating on the substrate then letting it dry.

The coating acts as both a protective shield and insulative material for a pcb.

Acrylic conformal coating is recognized for its high dielectric strength and fair moisture and abrasion resistance.

The fifth coating type parylene is applied using a unique vapor phase polymerization process.

Today we are going to discuss conformal coating pcb its benefits types and methods that might be helpful for you.

Conformal coating material is a thin polymeric film which conforms to the contours of a printed circuit board to protect the board s components.

Afa optically clear acrylic conformal coating ideally suited for use as an led coating or in other commercial applications to protect the pcb from the environment.

Its primary purpose is to protect electronics from environmental elements and corrosion.

Conformal coating is a polymeric film that covers and conforms to circuit board components and other electronics.

What generally distinguishes acrylic coating from other resins is ease of removal.